One of the key benefits of BIM is the ability to spot 'clashes' at an early stage in your project where they should be much easier, cheaper and less time consuming to rectify.

What is a clash?

In design terms a clash occurs when components that make up a built asset are not spatially co-ordinated and conflict. In a BIM process these clashes can be spotted more easily during the design phase of a project ahead of work starting on site.

Why do clashes occur?

A range of disciplines come together to work on different aspects of construction projects. Using the architect's model as a starting point a structural engineer, environmental engineer, mechanical and electrical engineer (and potentially many others) will each produce their own model. Each 'model' will consist of a range of model files, documents and structured data files containing non-geometric information about what is being built. All these assets come together as a digital replica. This will, at first, show what has been designed and will eventually show what has been built and installed.

In a Level 2 BIM process the federated models produced by individual teams are integrated (at pre-determined intervals) into a master model that sits inside of the Common Data Environment (CDE). With data from a multitude of models coming together to form a master model it is inevitable that there will be clashes that need to be resolved.

What types of clashes are there?

When we imagine clashes we commonly think of two components occupying the same space. These are often referred to as a 'hard clash' - a column running though a wall or pipework through a steel beam, for example. These kinds of clashes can be time consuming and costly to put right if only discovered onsite.

A 'soft clash' occurs when an element isn't given the spatial or geometric tolerances it requires or its buffer zone is breached. For example, an air conditioning unit may require certain clearances to allow for maintenance, access or safety that a steel beam would negate. Given sufficient object data, software can even be used to check adherence to relevant regulations and standards.

Other kinds of clash might involve the scheduling of contractors, the delivery of equipment and materials, and general timeline conflicts. These are often referred to as 'Workflow or 4D clashes'.

How can clashes be avoided?

Clash avoidance is a key part of the design and construction process. Documenting a set of standard procedures in a BIM Execution Plan (BEP) and setting out procedures for co-ordination in Employer's Information Requirements (EIR) as part of a project's contract documentation are crucial. So too are the BIM Execution Plans authored by suppliers. During the design and construction process, design team interface managers should assess design decisions and clashes to see if they can resolve them internally, and where this cannot be done, separate models may be combined for review by a design lead.

How are clashes spotted?

The traditional design process would see specialists working on separate drawings with tracing papers produced during co-ordination checkpoints to check for compatibility. It wasn't that unusual for clashes to only be spotted on the construction site with the potential of huge costs and delays.

The traditional design process would see specialists working on separate drawings with tracing papers produced during co-ordination checkpoints to check for compatibility. It wasn't that unusual for clashes to only be spotted on the construction site with the potential of huge costs and delays.

In a Level 2 BIM process a range of federated models are produced and co-ordinated data drops used to inform a master model. BIM modelling software and BIM integration tools allow designers to check for clashes in their own models and when models are combined.

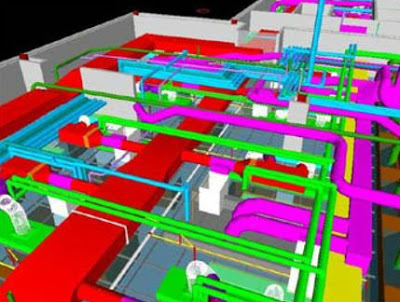

Clash detection software is becoming increasingly sophisticated, allowing the user to check for clashes within specific subsets (structural elements against walls, for example) and for these to be flagged on screen (often in vibrant colours).

Some geometric clashes will always be perfectly acceptable (think: recessed ceiling lights, pipes embedded within walls) and software rules that draw on embedded object data can stop these kinds of clashes being flagged. As you can imagine the level of detail in BIM modelling is, therefore, crucial when it comes to clash detection.

How are clashes resolved?

Running a clash detection scan or report will typically bring up many duplicate instances of the same issue. If a single run of pipework clashes with five beams, it will show as five clashes though, in reality, resolving one issue (the placement of the pipework) will solve all clashes. Reviewing and cancelling these clashes in the design is a key part of the BIM process. As with any automated process these kinds of scans should not be relied upon in isolation and should form part of wider design co-ordination processes.

What does the future hold for clash detection?

Software tools are likely to continue to become increasingly sophisticated as ever-richer data in standard formats are combined into models. The greatest potential for improvement however comes with Level 3 BIM. Working on one collaborative, co-ordinated building model (rather than the numerous federated models brought together to form a single complete model at key stages) should mean that the number of project clashes are dramatically reduced.

See also: BIM Levels explained

To keep up-to-date with future articles in this topic area - why not sign up to the NBS eWeekly newsletter? Get the latest content from theNBS.com carefully crafted into a handy weekly email.