My first thoughts on hearing about BIM (Building Information Modelling) were: how is this going to work?, so

My first thoughts on hearing about BIM (Building Information Modelling) were: how is this going to work?, so  writes Vicky Evans, Managing Director at Twinfix

writes Vicky Evans, Managing Director at Twinfix ![]() . A great concept in theory, but how will the practicalities work and will it help drive efficiencies, or will it just be more work? We all work in high-pressure environments where time is money, and we must look at which activities add value and which do not. Certainly for a relatively small manufacturer like ourselves, we need to be careful when deciding what we sign up to, so my initial thoughts on BIM were somewhat reserved.

. A great concept in theory, but how will the practicalities work and will it help drive efficiencies, or will it just be more work? We all work in high-pressure environments where time is money, and we must look at which activities add value and which do not. Certainly for a relatively small manufacturer like ourselves, we need to be careful when deciding what we sign up to, so my initial thoughts on BIM were somewhat reserved.

The idea of a model showing every detail of a building which can be manipulated seemed very science fiction. It led me to wonder how it would work in practice and whether specifiers and the industry will actually use it.

Our BIM journey began with the BIM day in Manchester and embracing the BIM challenge. I embarked on the two-day conference with mixed feelings. However, it was soon apparent that BIM was exciting and, although challenging, was fundamentally an efficient and forward-thinking way of constructing a

building. I began to feel excited by this new and challenging prospect.

I quickly started to understand how BIM could benefit us, both at specification stage and throughout the whole design process.

So, as I began to learn about this new concept, terms like COBie (Construction Operations Building Information Exchange) began to make sense. I quickly started to understand how BIM could benefit us, both at specification stage and throughout the whole design process. I felt assured that the upfront work needed for BIM would have long-term gains. Preparing the objects that contain the information you need means less rework, less duplication and a much smarter way of working. As we all know, working smarter is the sensible way forward.

So, as I began to learn about this new concept, terms like COBie (Construction Operations Building Information Exchange) began to make sense. I quickly started to understand how BIM could benefit us, both at specification stage and throughout the whole design process. I felt assured that the upfront work needed for BIM would have long-term gains. Preparing the objects that contain the information you need means less rework, less duplication and a much smarter way of working. As we all know, working smarter is the sensible way forward.

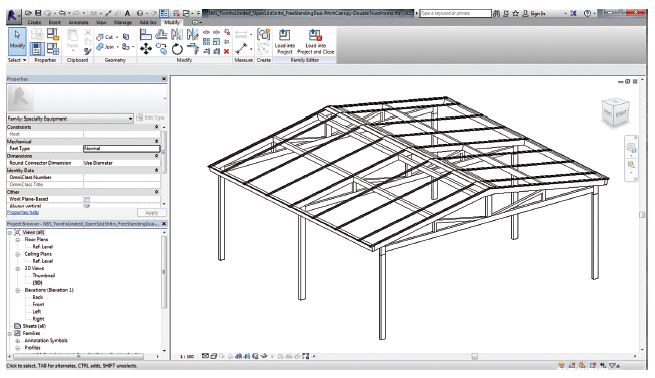

So we embraced the concept and commissioned NBS to author our canopy products. They worked with one of our in-house designers to construct our rather complex models, understanding how our canopies worked. Once completed, I went into the webinar where NBS demonstrated our products with bated breath, concerned about how they would look. I need not have worried as they worked better than anticipated. In fact, the result was a good-looking, rather clever object that was easy to understand and manipulate.

I believe we are the first canopy manufacturer to have these objects and I’m very proud that Twinfix took this bold step.

The future is here. We have BIM. We have a 3D printer. And most importantly, we are a British manufacturing company embracing the future… How exciting! The science fiction that I believed BIM to be is now very much a reality.